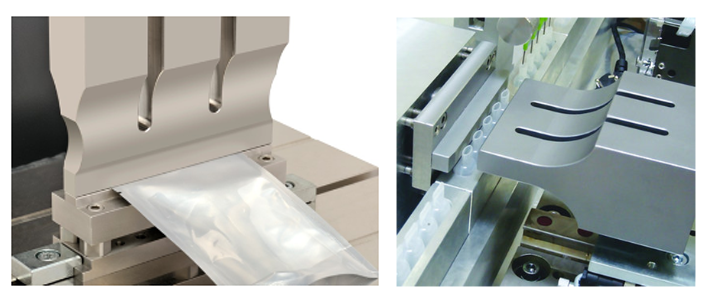

The packaging sector is where ultrasonic technology finds a broad spectrum of uses: installing ultrasonic enclosing systems on a classic line, it is possible to solder and incise plastic made packaging of any kind and dimensions. Soldering sonotrodes remain cold during such procedure, thus avoiding potential damage to heat-sensitive materials. In addition, this cold process reduces machinery maintenance and cleaning costs, since tools don’t get contaminated with residual particles.

Advantages

Perfect results even on areas that are not completely uncontaminated

Perfect results even on areas that are not completely uncontaminated No foreign particles on the binding surface

No foreign particles on the binding surface Non-stick gear

Non-stick gear Reduced processing times

Reduced processing times Less cleaning efforts

Less cleaning efforts Ultrasonic waves are safe, reliable, fast and can be applied in countless products

Ultrasonic waves are safe, reliable, fast and can be applied in countless products Shorter sealing, welding and cooling times

Shorter sealing, welding and cooling times Increased production speed

Increased production speed Lower energy costs

Lower energy costs High quality sealing / welding in contaminated area

High quality sealing / welding in contaminated area No warm up time

No warm up time Sonotrodes work cold and remain clean longer

Sonotrodes work cold and remain clean longer Maintenance or cleaning tasks not required./li>

Maintenance or cleaning tasks not required./li>